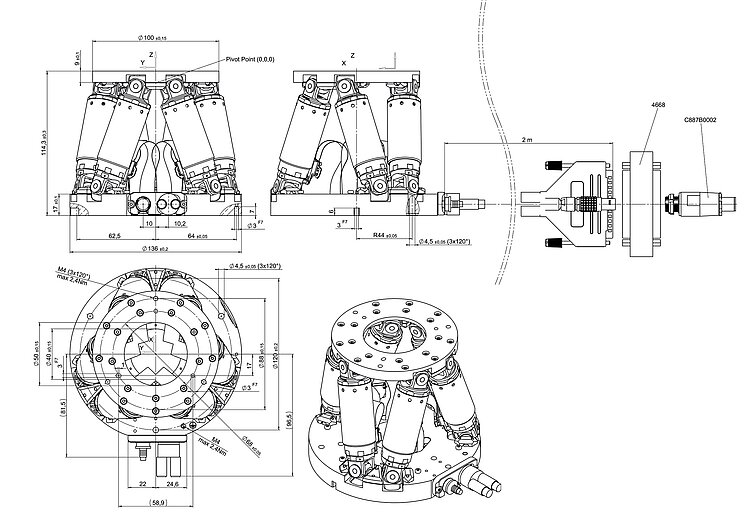

Miniature hexapod; BLDC motor; vacuum compatible to 10-6hPa; 5 kg payload; 10 mm/s velocity; 2 m cable length (vacuum side); feedthroughs. Air-side connecting cables are not included in the scope of delivery and must be ordered separately.

H-811.I2V Vacuum Compatible Miniature Hexapod

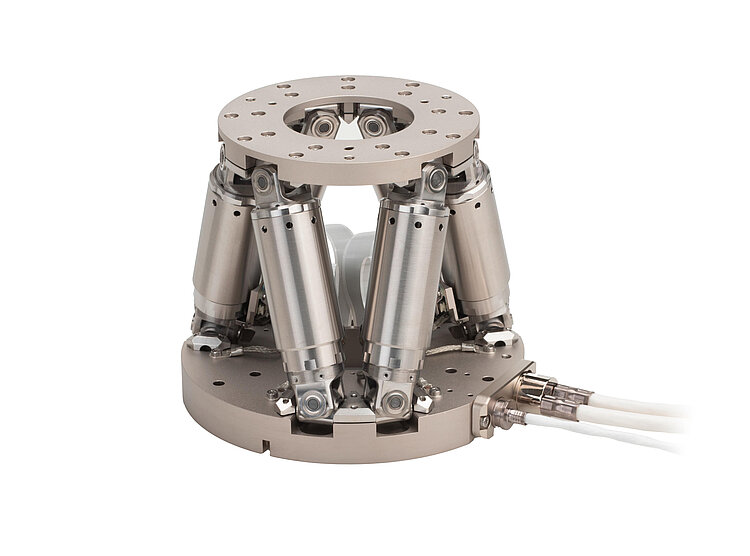

Compact and Highly Precise

- Vacuum to 10-6 hPa

- Travel range ±17 mm / ±16 mm / ±6.5 mm

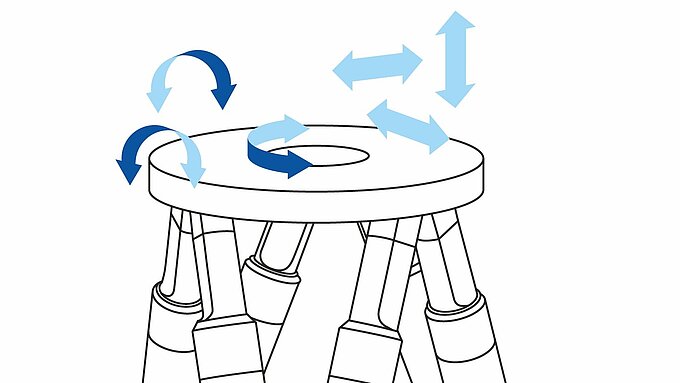

- Rotation range ±10° / ±10° / ±21°

- Minimum incremental motion 0.2 µm / 0.2 µm / 0.08 µm

- Repeatability to ±0.06 µm

- Payload 5 kg

Application fields

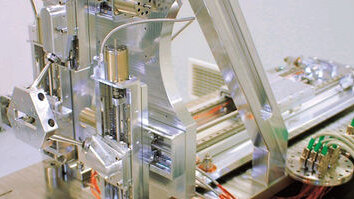

Thanks to its small footprint, the vacuum variant of the H-811 is well suited for installation in vacuum chambers. Its high level of precision enables the H-811.I2V to execute alignment processes extremely precisely and efficiently. In such areas, it makes a significant contribution to boosting the productivity of complex manufacturing processes and measuring procedures.

High dynamics combined with extreme reliability

The parallel-kinematic arrangement enables the hexapod to perform motion in 6 axes in an extremely compact design. Thanks to the use of brushless DC motors and its stiff mechanical design, the H-811 offers the dynamics required for active alignment applications, even if external interference (e.g., in the case of gluing processes) occurs. Extensive software tools provide support by simplifying the system tuning and making automatic routines available for alignment to an external analog control signal.

Motion simulation for protecting the overall system

The PIVirtualMove software, which can be downloaded free of charge, simulates the travel range, the alignment, and the permissible forces and torques of the H-811 to facilitate an optimum system configuration. In this context, both the chosen center of rotation and the center of gravity of the load are taken into consideration.

Work and tool coordinate systems and an emulation tool are included in the free software package belonging to the scope of delivery of the hexapod controller. The tools provided help to protect critical components such as optical or photonic parts.

Specifications

Datasheet H-811.I2V

Specifications

| Motion | H-811.I2V | Tolerance |

|---|---|---|

| Active axes | X ǀ Y ǀ Z ǀ θX ǀ θY ǀ θZ | |

| Travel range in X | ± 17 mm | |

| Travel range in Y | ± 16 mm | |

| Travel range in Z | ± 6.5 mm | |

| Rotation range in θX | ± 10 ° | |

| Rotation range in θY | ± 10 ° | |

| Rotation range in θZ | ± 21 ° | |

| Maximum velocity in X | 10 mm/s | |

| Recommended velocity in X | 5 mm/s | |

| Maximum velocity in Y | 10 mm/s | |

| Recommended velocity in Y | 5 mm/s | |

| Maximum velocity in Z | 10 mm/s | |

| Recommended velocity in Z | 5 mm/s | |

| Maximum angular velocity in θX | 250 mrad/s | |

| Recommended angular velocity in θX | 120 mrad/s | |

| Maximum angular velocity in θY | 250 mrad/s | |

| Recommended angular velocity in θY | 120 mrad/s | |

| Maximum angular velocity in θZ | 250 mrad/s | |

| Recommended angular velocity in θZ | 120 mrad/s | |

| Positioning | H-811.I2V | Tolerance |

| Minimum incremental motion in X | 0.2 µm | typ. |

| Minimum incremental motion in Y | 0.2 µm | typ. |

| Minimum incremental motion in Z | 0.08 µm | typ. |

| Minimum incremental motion in θX | 2.5 µrad | typ. |

| Minimum incremental motion in θY | 2.5 µrad | typ. |

| Minimum incremental motion in θZ | 5 µrad | typ. |

| Unidirectional repeatability in X | ± 0.15 µm | typ. |

| Unidirectional repeatability in Y | ± 0.15 µm | typ. |

| Unidirectional repeatability in Z | ± 0.06 µm | typ. |

| Unidirectional repeatability in θX | ± 2 µrad | typ. |

| Unidirectional repeatability in θY | ± 2 µrad | typ. |

| Unidirectional repeatability in θZ | ± 3 µrad | typ. |

| Backlash in X | 0.2 µm | typ. |

| Backlash in Y | 0.2 µm | typ. |

| Backlash in Z | 0.06 µm | typ. |

| Backlash in θX | 2 µrad | typ. |

| Backlash in θY | 2 µrad | typ. |

| Backlash in θZ | 4 µrad | typ. |

| Drive Properties | H-811.I2V | Tolerance |

| Drive type | Brushless DC motor | |

| Mechanical Properties | H-811.I2V | Tolerance |

| Stiffness in X | 0.7 N/µm | |

| Stiffness in Y | 0.7 N/µm | |

| Stiffness in Z | 8 N/µm | |

| Maximum load capacity, base plate in any orientation | 2.5 kg | |

| Maximum load capacity, base plate horizontal | 5 kg | |

| Maximum holding force, base plate in any orientation | 2.5 N | |

| Maximum holding force, base plate horizontal | 15 N | |

| Overall mass | 2.2 kg | |

| Material | Stainless steel, aluminum | |

| Miscellaneous | H-811.I2V | Tolerance |

| Operating temperature range | 0 to 50 °C | |

| Vacuum class | 10⁻⁶ ǀ hPa | |

| Maximum bakeout temperature | 80 °C | |

| Connector for data transmission | HD D-sub 78 (m) | |

| Connector for supply voltage | LEMO | |

| Cable length | 2 m | |

| Outer diameter power supply cable | 4.7 mm | |

| Minimum bending radius for fixed installation, power supply | 50 mm | |

| Outer diameter data transmission cable | 6.6 mm | |

| Minimum bending radius for fixed installation, data transmission | 70 mm | |

| Recommended controllers/drivers | C-887.5x |

The cables fixed to the H-811.I2V are not drag chain compatible.

Note on outer diameter data transmission cable: The data transmission connection consists of 2 cables that end in one connector. The specified diameter applies for each cable.

Air-side connecting cables are not included in the scope of delivery and must be ordered separately.

With continuous operation in a vacuum, heat generation may necessitate limiting the operating parameters.

When measuring position specifications, typical velocity is used. The data is included in the delivery of the product in the form of a measurement report and is stored at PI.

The maximum travel ranges of the individual coordinates (X, Y, Z, θX, θY, θZ) are interdependent. The data for each axis shows its maximum travel range when all other axes are in the zero position of the nominal travel range and the default coordinate system is in use, or rather when the pivot point is set to 0,0,0.

At PI, technical data is specified at 22 ±3 °C. Unless otherwise stated, the values are for unloaded conditions. Some properties are interdependent. The designation "typ." indicates a statistical average for a property; it does not indicate a guaranteed value for every product supplied. During the final inspection of a product, only selected properties are analyzed, not all. Please note that some product characteristics may deteriorate with increasing operating time.

Downloads

Product Note

Product Change Notification H-811.I2V

Datasheet

Datasheet H-811.I2V

Documentation

Short Instructions MS247EK

Hexapod Systems: Hexapod H-8x with C-887.5x Controller

User Manual MS235

H-811 Miniature Hexapods

Technical Note H811T0001

Technical note for unpacking the hexapod

3D Models

H-811.I2V 3D Model

Software Files

PIVirtualMove

Livre Blanc

Industrial Safety Device for Hexapods

How to Connect a Safety Light Barrier to a Hexapod System

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Comment obtenir une offre de prix

Contactez un ingénieur!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

Technologie

Connectivité EtherCAT des produits PI

PI offers high-precision drives for use as EtherCAT slave, or integrates with ACS Motion Controllers as Master, or 2nd Master in an existing architecture.

Un hexapode comme simulateur de mouvement

Les simulateurs de mouvement ont des exigences plus élevées en matière de dynamique de mouvement (shaker).

Positionneurs multiaxes

Les plateformes hexapode sont utilisées pour le positionnement de précision et l'alignement de charges selon six degrés de liberté, trois axes linéaires et trois axes rotatifs.

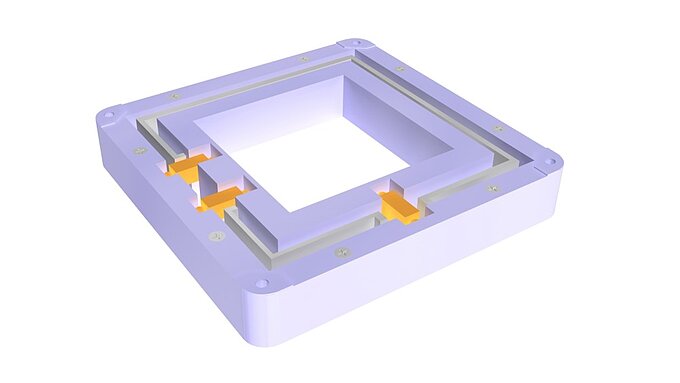

Systèmes de positionnement piézo avec cinématique parallèle

In a parallel-kinematic, multi-axis system, all actuators act directly on a single moving platform.

Cinématique parallèle

In a parallel-kinematic, multi-axis system, all actuators act directly on a single moving platform. This means that all axes can be designed with identical dynamic properties, thus reducing the moved mass considerably. Hexapods are used for moving and precision positioning, aligning and displacing loads in all six degrees of freedom, i.e., three linear and three rotational axes.

Vide

Manipulation précautionneuse, locaux adéquats : PI dispose non seulement de l'équipement nécessaire pour la qualification de matériaux, de composants et de produits finis mais s'appuie aussi sur de nombreuses années d'expérience en matière de systèmes de positionnement sous vide et ultra vide.

Applications

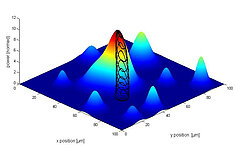

Sample Adjustment

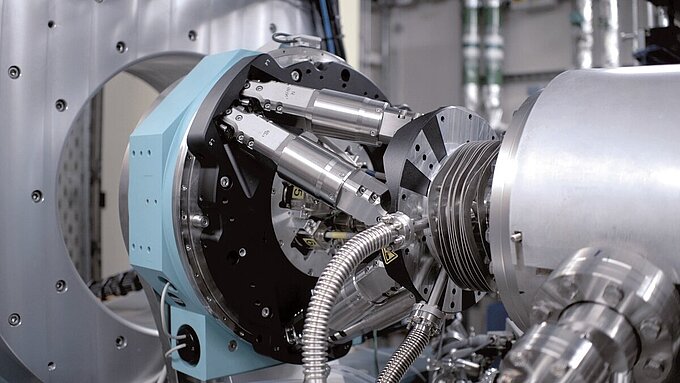

At Diamond Light Source, UK, beamline I07 is a high-resolution X-ray diffraction beamline dedicated to investigate the structure of surfaces and interfaces.

High Vacuum Positioning

Investigation of the structural properties of thin films under high-vacuum conditions.

Sample Positioning in High-Vacuum

Sample Manipulators in High-Vacuum

Optics Hutch Instrumentation

At DESY in Hamburg, the P05 Imaging Beamline is operated by the HZG.