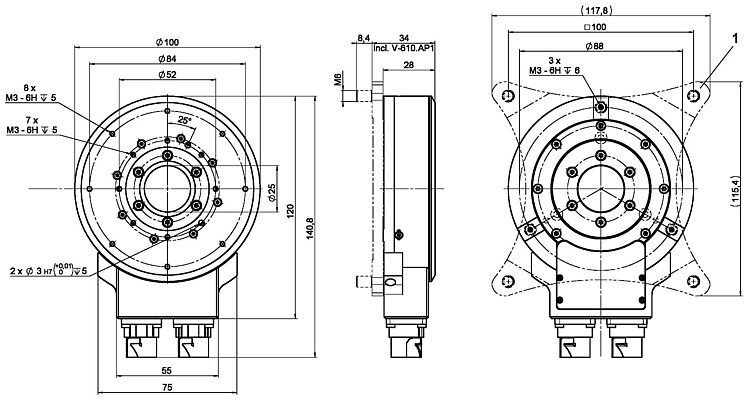

Compact PIMag® rotation stage, Ø 25 mm clear aperture, ironless 3-phase torque motor, incremental angle measuring system with sin/cos signal transmission

V-610 Compact PIMag® Rotation Stage

Flat Design at High-Torque for Loads up to 2 kg

- Flat and compact design

- Clear aperture for transmitted-light applications

- Optional holding brake

- Ironless PIMag® torque motor developed in-house for high drive torque

PIMag® torque motor

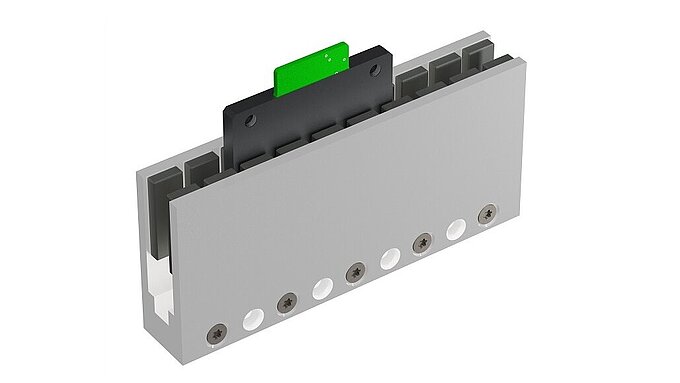

Torque motors are electromagnetic direct drives. They dispense with mechanical components in the drivetrain and transfer the drive force directly and friction-free to the motion platform. The drives reach high velocities and accelerations. Ironless motors are particularly suitable for positioning tasks with the highest demands on precision because there is no undesirable interaction with the permanent magnets. This allows smooth running even at the lowest velocities and at the same time, there is no vibration at high velocities. Nonlinearity in control behavior is avoided and any position can be controlled easily. The drive force can be set freely.

PIMag®

PI develops proprietary magnetic motors if positioning systems need to achieve specific performance characteristics that cannot be reached by using drive components currently available on the market, for example, to achieve a high force density or a compact design. The motors developed in-house are identified by the PIMag® brand name.

Application fields

Sample inspection. Precision microassembly. Research. Biotechnology. Semiconductor technology. Measuring technology. Automation.

Specifications

Datasheet V-610

Specifications

| Motion | V-610.998061 | V-610.998061B | Tolerance |

|---|---|---|---|

| Active axes | θZ | θZ | |

| Rotation range in θZ | 360 ° | 360 ° | |

| Maximum angular velocity in θZ, unloaded | 500 rpm | 500 rpm | |

| Positioning | V-610.998061 | V-610.998061B | Tolerance |

| Minimum incremental motion in θZ | 2 µrad | 2 µrad | typ. |

| Unidirectional repeatability in θZ | ± 2 µrad | ± 2 µrad | typ. |

| Bidirectional repeatability in θZ | 176 µrad | 176 µrad | typ. |

| Reference switch | 1 / revolution, differential pulse over one sensor signal period, 1 V peak-peak | 1 / revolution, differential pulse over one sensor signal period, 1 V peak-peak | |

| Integrated sensor | Incremental angle-measuring system | Incremental angle-measuring system | |

| Sensor signal | Sin/cos, 1 V peak-peak | Sin/cos, 1 V peak-peak | |

| Sensor signal periods / U | 1845 | 1845 | |

| Sensor resolution, rotational | 9 µrad | 9 µrad | |

| Drive Properties | V-610.998061 | V-610.998061B | Tolerance |

| Drive type | Ironless 3-phase torque motor | Ironless 3-phase torque motor | |

| Nominal voltage | 48 V | 48 V | max. |

| Nominal current, RMS | 2.05 A | 2.05 A | typ. |

| Peak current, RMS | 5 A | 5 A | typ. |

| Drive torque clockwise in θZ | 0.49 N·m | 0.49 N·m | max. |

| Drive torque counterclockwise in θZ | 0.49 N·m | 0.49 N·m | max. |

| Peak torque clockwise in θZ | 1.25 N·m | 1.25 N·m | max. |

| Peak torque counterclockwise in θZ | 1.25 N·m | 1.25 N·m | max. |

| Torque constant | 0.24 N·m/A | 0.24 N·m/A | typ. |

| Resistance phase-phase | 3 Ω | 3 Ω | typ. |

| Inductance phase-phase | 0.5 mH | 0.5 mH | |

| Back EMF, phase-phase, rotational | 25.1 V/kRPM | 25.1 V/kRPM | max. |

| Number of pole pairs | 12 | 12 | |

| Mechanical Properties | V-610.998061 | V-610.998061B | Tolerance |

| Permissible push force in Y | 6 N | 6 N | max. |

| Permissible push force in Z | 20 N | 20 N | max. |

| Moment of inertia in θZ, unloaded | 411.84 kg·mm² | 418.23 kg·mm² | ±20 % |

| Moved mass in θZ, unloaded | 380 g | 400 g | ±5 % |

| Bearing type | Crossed roller bearings | Crossed roller bearings | |

| Overall mass | 705 g | 965 g | ±5 % |

| Mass without cable | 630 g | 870 g | |

| Material | Aluminum, anodized | Aluminum, anodized | |

| Holding brake | — | Electromagnetic safety brake | |

| Miscellaneous | V-610.998061 | V-610.998061B | Tolerance |

| Operating temperature range | 10 to 50 °C | 10 to 50 °C | |

| Connector | M15 | M15 | |

| Sensor connector | M15 | M15 | |

| Recommended controllers / drivers | C-891, C-885 with C-891.11C885 ACS modular controller | C-891, C-885 with C-891.11C885 ACS modular controller |

Travel range: ±5 turns with C-891 controller / controller module

Nominal torque/current and peak torque/current: Depending on the surface. Specification based on mounting on an aluminum surface, with 600 mm × 300 mm × 12.7 mm (l × w × h).

C-891/C-885: Separate connection cable required for motor and sensor connection respectively

At PI, technical data is specified at 22 ±3 °C. Unless otherwise stated, the values are for unloaded conditions. Some properties are interdependent. The designation "typ." indicates a statistical average for a property; it does not indicate a guaranteed value for every product supplied. During the final inspection of a product, only selected properties are analyzed, not all. Please note that some product characteristics may deteriorate with increasing operating time.

Downloads

Datasheet

Datasheet V-610

Documentation

User Manual V610UM0001

V-610.998061 PIMAG® RotationStage

User Manual V610UM0002

V-610.998061B PIMAG® RotationStage

3D Models

V-610 3-D model

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

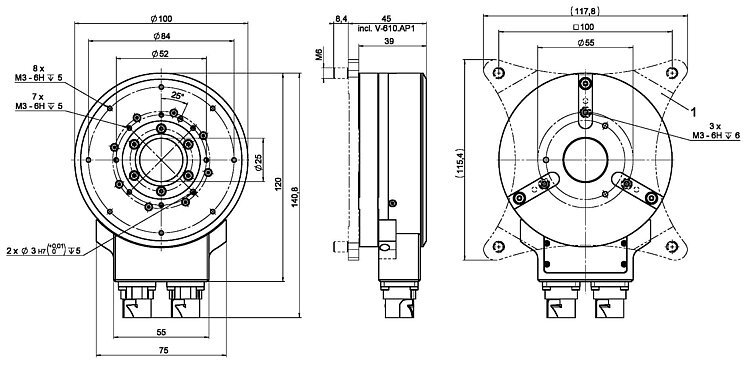

Compact PIMag® rotation stage, Ø 25 mm clear aperture, ironless 3-phase torque motor, incremental angle measuring system with sin/cos signal transmission, holding brake

Comment obtenir une offre de prix

Contactez un ingénieur!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.