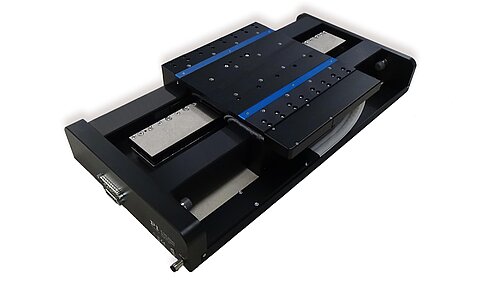

Stages with Magnetic Direct-Drive Linear Motor

The friction-free magnetic direct drive principle allows for most dynamic stages. Compared with motor-spindle-based stages, they use fewer mechanical components which results in less friction and backlash and thus more precision.

PI’s PIglide stages combine the magnetic direct drive with highly precise preloaded air bearings for even better performance.

PIMag®

PI has many standard and customer-specific positioning solutions on offer that are equipped with magnetic direct drives; the company has also many years of experience in the design, construction, and manufacture of the necessary system components such as guides, sensors, control technology, and software. PI can also develop proprietary magnetic motors if positioning systems need to achieve specific performance characteristics that cannot be reached by using drive components currently available on the market, for example, to achieve a high force density or a compact design. These >> proprietary motors, developed in-house, are identified by the PIMag® brand name.