NEXACT® OEM miniature linear motor / actuator; NEXACT® piezo walking drive; 20 mm travel range; 10 N drive force; 10 mm/s maximum velocity; 1.5 m cable length

N-310 NEXACT® OEM Miniature Linear Motor / Actuator

Compact, Fast, with Long Travel Range, PiezoWalk® Principle

- Travel range 20 mm

- Compact in size, inexpensive design

- Resolution to 0.03 nm

- Drive force up to 10 N

Nanometer precision and high feed force with PiezoWalk® walking drives

In the PiezoWalk® walking drive, several piezo actuators do a walking motion that leads to a forward feed of a runner. Control of the actuators allows the smallest step and forward feed motion at a resolution of well under one nanometer.

Highly accurate position measuring with incremental linear encoder

Noncontact optical linear encoders measure the position directly at the platform with the greatest accuracy. Nonlinearity, mechanical play or elastic deformation have no influence on the measurement.

Application fields

- Industrial precision positioning

- Semiconductor technology

- Semiconductor tests

- Wafer inspection

- Lithography

- Nanoimprinting

- Nanometrology

Specifications

Datasheet N-310

Specifications

| Motion | N-310.11 | Tolerance |

|---|---|---|

| Active axes | X | |

| Travel range in X | 20 mm | |

| Travel range in X (analog mode) | 10 µm | max. |

| Maximum velocity in X, unloaded | 10 mm/s | |

| Positioning | N-310.11 | Tolerance |

| Step size in full step mode | 10 µm | |

| Resolution in X, open loop | 0.03 nm | typ. |

| Drive properties | N-310.11 | Tolerance |

| Drive type | NEXACT® piezo walking drive | |

| Operating voltage | -10 to +45 V | |

| Drive force in X | 10 N | typ. |

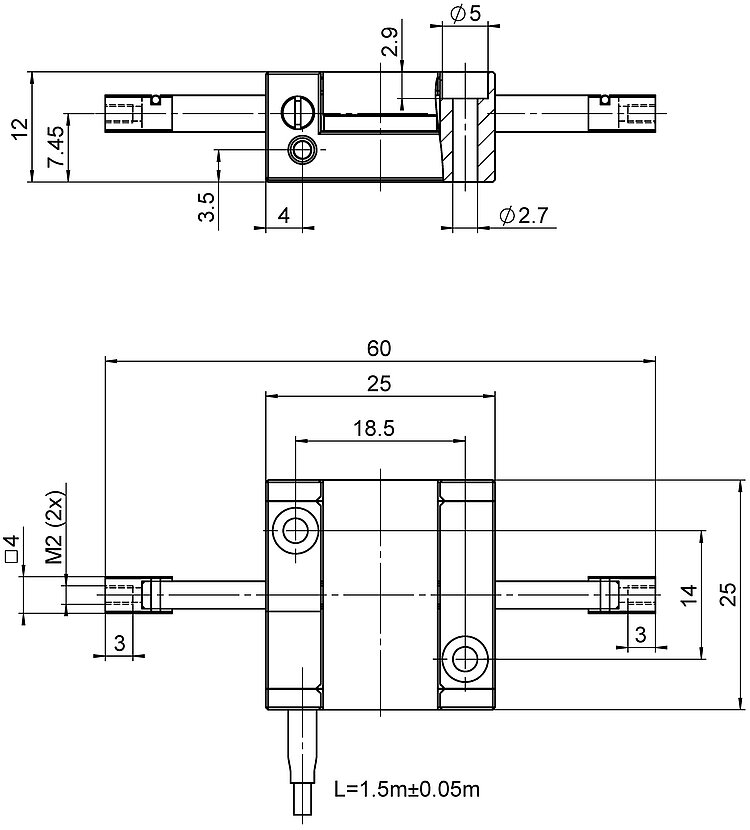

| Mechanical properties | N-310.11 | Tolerance |

| Holding force in X, passive | 12 N | max. |

| Overall mass | 50 g | ±5 % |

| Material | Stainless steel, ceramic; cable: PFA, PTFE | |

| Miscellaneous | N-310.11 | Tolerance |

| Operating temperature range | 0 to 50 °C | |

| Connector | HD D-sub 15 (m) | |

| Cable length | 1.5 m | ±50 mm |

| Recommended controllers/drivers | E-713, E-861, E-861.11C885 |

Maximum velocity in X, unloaded: depending on the drive electronics

Resolution in X, open loop: depending on the drive electronics

At PI, technical data is specified at 22 ±3 °C. Unless otherwise stated, the values are for unloaded conditions. Some properties are interdependent. The designation "typ." indicates a statistical average for a property; it does not indicate a guaranteed value for every product supplied. During the final inspection of a product, only selected properties are analyzed, not all. Please note that some product characteristics may deteriorate with increasing operating time.

Downloads

Datasheet

Datasheet N-310

Documentation

User Manual N310T0012

N-310 NEXACT® OEM Miniature Linear Drive

3D Models

N-310.11 3D Model

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Comment obtenir une offre de prix

Contactez un ingénieur!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

Technologie

Moteurs PiezoWalk®

PiezoWalk® drives were developed more than 10 years ago for the semiconductor industry, a demanding industry when it comes to reliability, position resolution and long-term stability.

Positionneurs multiaxes

Les plateformes hexapode sont utilisées pour le positionnement de précision et l'alignement de charges selon six degrés de liberté, trois axes linéaires et trois axes rotatifs.

Vide

Manipulation précautionneuse, locaux adéquats : PI dispose non seulement de l'équipement nécessaire pour la qualification de matériaux, de composants et de produits finis mais s'appuie aussi sur de nombreuses années d'expérience en matière de systèmes de positionnement sous vide et ultra vide.