High Dynamics Focus Shift for Laser Beam Welding & Cutting

High Process Speed and Quality Through Controlled Energy Distribution

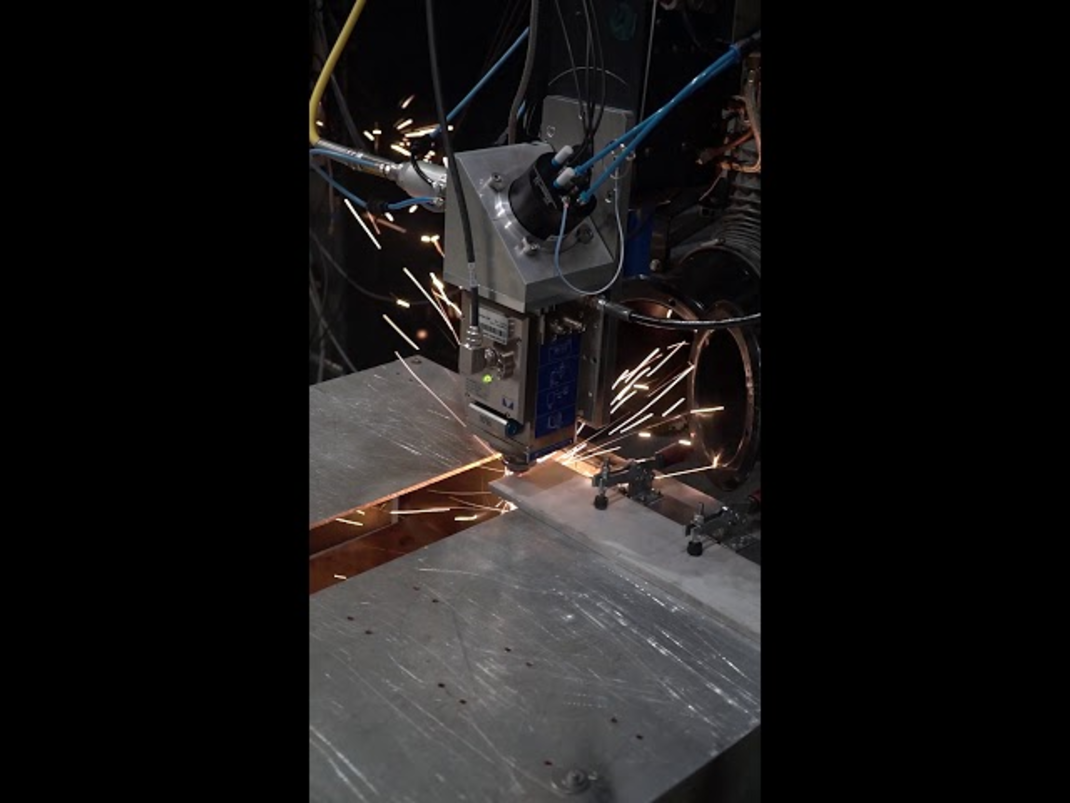

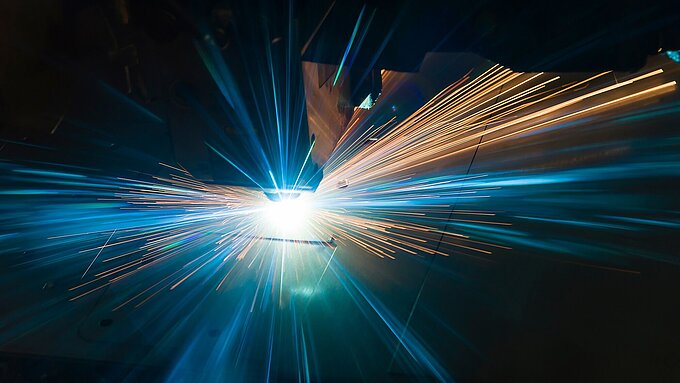

Lasers are used today in a wide variety of industrial applications in order to further optimize production processes and guarantee high workpiece quality. Laser machining processes can as well be significantly improved by high-frequency oscillation of the laser beam in the XY plane. Increasing requirements in industry, however, demand not only a fast motion in the plane, but also a fast active vertical shift of the beam energy in the workpiece, e.g. to further increase the usable feed rate during laser beam cutting of thick sheet metal or to enable better weld seam quality and process stability during laser beam welding. With a new Z axis focus shifter module, it is possible to extend the conventional methods and also 2-D beam manipulation in the XY machining plane by a highly dynamic movement in the direction of the beam axis, thereby increasing the machining speed and improving the machining quality.

Benefits of the High Dynamics Z Axis Focus Shifter Module

Features of the Z Axis Focus Shifter Module

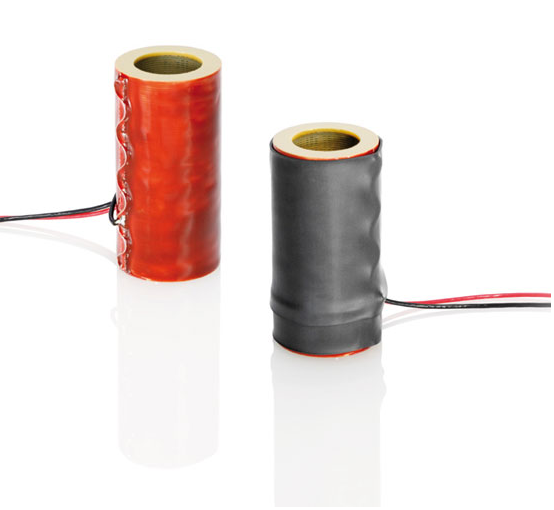

- Piezo-based aspheric membrane deformation to avoid imaging errors

- Elliptical mirror substrate for maximum beam aperture exhaustion

- Dielectric coating for high reflectivity

- Use of >> PICA Thru© Ring Actuators

The Z axis focus shifter module was developed within the framework of the PISTOL3 project in cooperation between PI, Fraunhofer IOF, Fraunhofer IWS and the industrial partners Kjellberg Finsterwalde, Heliatek and Optics Balzers. The PISTOL3 project is part of the “Zwanzig20-Partnerschaft für Innovation” funding program that is supported by the >> German Federal Ministry of Education and Research, the Bundesministerium für Bildung und Forschung (BMBF).

Downloads

Automation Platforms for Laser Material Processing

Precision – Throughput – Synchronized Motion