G-910.RC02 Motion Controller for Low Power Requirement

Integrated Driver for up to 2 Axes, EtherCAT Master for Synchronizing up to 4 Axes

- ACS motion controller with integrated ACS driver module

- Upgradable to up to 4 axes with the G-910.RC01 driver module

- Directly compatible with positioners from PI

- For AC servo motors / brushless DC motors, brushed DC motors, voice coil motors, stepper motors

- Output power 120 W at 24 V or 280 W at 48 V

- Many options for trajectory planning

Overview

The G-910 motion controller offers a fully integrated electronics solution with controller and driver module in a compact housing. The G-910.RC02 motion controller features the state-of-the-art ACS SPiiPlusEC motion controller and EtherCAT master. Integrated driver module for 2 axes, upgradable via EtherCAT to up to 4 synchronized axes. EtherCAT cycle and generation rate of the motion profile 2 kHz. Ethernet velocity of up to 1 GbE. Servo algorithms for advanced gantry and dual-loop control.

Encoder

Supports incremental encoders (sine/cosine or RS-422) and absolute encoders (EnDat 2.2 & 2.1, Smart-Abs, Panasonic, BiSS-A/B/C (SSI)). Depending on the application, the encoders can respectively be led to the motor interface or the separate sensor interface.

I/O lines

The digital inputs and outputs can be flexibly configured. For the evaluation of reference switches, digital inputs can alternatively be led to the motor connectors. Depending on the application, the inputs for the limit and reference switches can be configured for 5 V or 24 V and also as PNP or NPN inputs. Position synchronous trigger signals with up to 10Mhz output frequency make a precise process control at high travel velocities possible (position event generator – PEG).

Communication, software support

The motion controller works as master in an internal EtherCAT network. The open network architecture also allows the integration of third-party components. For communication with a PC, the motion controller is equipped with an Ethernet TCP/IP and a RS-232 interface. ACS SPiiPlus MMI Application Studio, a modern user software with tools for control tuning and visualizing is included in the scope of delivery. Programming libraries are available for C/C++, COM, .NET, MATLAB.

Configuration

If the types of positioner are specified when ordering, all connectors of the G-910.RC02 are suitably preconfigured at delivery. The default factory configuration, without positioner-specific adjustments, is detailed in the specifications. For subsequent adjustments, please contact our service department.

Specifications

Datasheet G-910.RC02

Specifications

G-910.RC0242100 / G-910.RC0242200 | |

|---|---|

Function | ACS SPiiPlusEC controller with the ACS UDMnt driver module, with connectors for positioners from PI |

Version | Benchtop device |

Motor types | 2 and 3-phase AC servo motors / brushless DC motors, brushed DC motors, voice coil motors, stepper motors |

Number of drive axes | 2 Upgradable via EtherCAT with additional driver module to up to 4 synchronized axes. |

Motion and control | G-910.RC0242100 / G-910.RC0242200 |

|---|---|

Controller type | Cascading PIV controller structure with velocity and acceleration feedforward control |

Sampling rate current control | 20 kHz |

Control algorithms | Gantry control, dual-loop control |

Motion profiles/trajectory planning | Multi-axis point-to-point, jog, tracking, and sequential multi-point motion Multi-axis segmented motion with look-ahead Arbitrary path with PVT cubic interpolation Third order profiles (S-Curve) Smooth on-the-fly change of target position or velocity Inverse/forward kinematics and coordinate transformations (at application level) Master-slave with position and velocity locking (electronic gear/cam) |

Encoder | 1 × per integrated axis, supported types: Incremental: 1Vss, RS-422 Absolute: EnDat 2.2 & 2.1, Smart-Abs, Panasonic, BiSS-A/B/C (SSI) |

Limit switches | 2 × per integrated axis Default: 5 V sinking (NPN) Optional configuration: 24 V; sourcing (PNP) |

Reference switch | Default: 1 × per integrated axis, 5 V sinking (NPN) Optional configuration: 24 V; sourcing (PNP); use as digital multipurpose inputs on digital I/O connector (HD D-sub 15 (f)) |

Motor brake | 1 × per integrated axis Integrated PWM brake driver with current reduction for a reduced heating up of the brake |

Interfaces and operation | G-910.RC0242100 / G-910.RC0242200 |

|---|---|

Motor connector | 2 × HD D-sub 26 (f) |

Sensor connector | 2 × D-sub 15 (m) or 2 × via the motor connectors Default factory configuration at delivery: Digital incremental encoder (RS-422) or absolute encoder on motor connector Incremental encoder 1 Vss on D-sub 15 (m) Possible modified factory configuration at delivery: Digital incremental encoder (RS-422) or absolute encoder on D-sub 15 (m) |

Digital I/O lines | HD D-sub 15 (f) and motor connectors: 2 × outputs PNP 24 V source; also control the drivers for the motor brakes Default for inputs: 2 × PNP 24 V source on HD D-sub 15 (f); in addition 2 × NPN 5 V sinking for reference switches on the motor connectors Optional configuration for inputs: 4 × PNP 24 V source on HD D-sub 15 (f) |

Analog I/O lines | HD D-sub 15 (m): 2 differential analog inputs: ±10 V, 12-bit 1 differential analog output: ±10 V, 10 bit |

Outputs for position event generator (PEG) | Parallel on HD D-sub 15 (m) and HD D-sub 15 (f): 2 differential outputs (RS-422) for pulses at programmable positions, pulse width 26 ns to 1.75 ms, max. 10 MHz; only possible with incremental encoder |

EtherCAT network | Up to 4 axes in an ACS EtherCAT network, also using EtherCAT third-party components. |

Control rate and EtherCAT clock rate | 2 kHz |

Communication interfaces | EtherCAT IN and OUT: RJ-45 Ethernet (TCP/IP, Modbus/TCP, EtherNet/IP): RJ-45 RS-232: D-sub 9 (m) |

User software | ACS SPiiPlus MMI Application Studio |

Application programming interfaces | Programming libraries for C/C++, COM, .NET, MATLAB available |

Programming | ACSPL+ real-time scripting language: Up to 10 simultaneously running programs (buffer) |

Miscellaneous | G-910.RC0242100 | G-910.RC0242200 |

|---|---|---|

Operating voltage intermediate circuit | 24 V DC from external power adapter, power adapter with 24 V DC (120 W) included in the scope of delivery | 48 V DC from external power adapter, power adapter with 48 V DC (280 W) included in the scope of delivery |

Operating voltage logic | 24 V DC from external power adapter, power adapter with 24 V DC (120 W) included in the scope of delivery | 24 V DC from external power adapter, power adapter with 24 V DC (120 W) included in the scope of delivery |

Max. current consumption intermediate circuit* | 5 A | 5 A |

Max. current consumption logic | 1.7 A | 1.7 A |

Operating temperature range | 5 to 40 °C (temperature protection switches off at excessively high temperatures) | 5 to 40 °C (temperature protection switches off at excessively high temperatures) |

Mass | 2.85 kg | 2.85 kg |

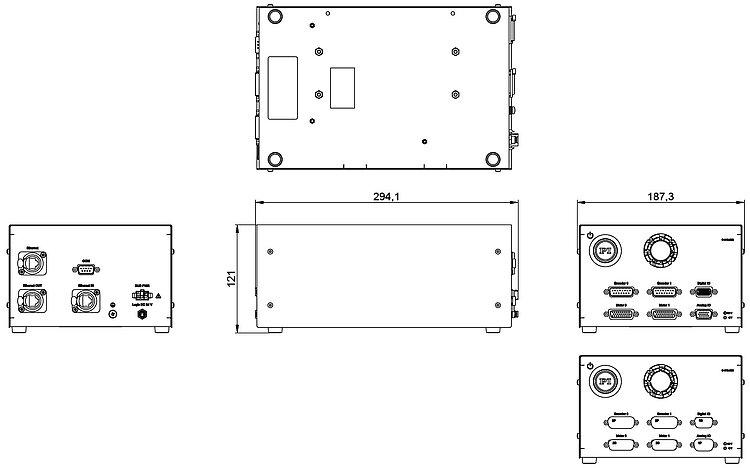

Dimensions | 187.3 mm × 121 mm × 294.1 mm | 187.3 mm × 121 mm × 294.1 mm |

Downloads

Datasheet

Datasheet G-910.RC02

Documentation

User Manual G910M0001

G-910.RC0242100 and G-910.RC0242200 ACS motion controllers with 24 V and 48 V intermediate circuit voltage and interfaces for PI positioners

Short Instructions MS256EK

ACS Motion Controllers and Drivers: G-900, G-901, G-902, G-910

3D Models

3-D model G-910.RC02

Quote / Order

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Add-on modules for driving additional axes (please order separately)

Comment obtenir une offre de prix

Contactez un ingénieur!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.